Continued creation of new business fields

Kyoseki Sangyo’s competitive advantage lies in its organizational structure where each of the three divisions operate their businesses in organic combination with those of other division’s. This has led to the continued creation of new business fields adapted to changing market needs. The R&D division engages in research and development with an eye on future needs, including nanotechnology studies which they expect will lead to innovations in a wide range of industries.

Mass-produced Nanoparticle R&D

With our eyes set on the needs of the future, we are currently researching low-cost, stable nanoparticle mass production technologies and have succeeded in making nanoparticles of some metals. Ultra-small nanoparticles have potential for various industrial applications in a wide range of fields such as high-integration semiconductors, food, medical care, and biotechnology.

Electron micrograph

of nanoparticles

(1nm at smallest)

Nanoparticle Syntheses

-

Palladium Pd

-

Silver Ag

-

Gold Au

Soldering Business

New Soldering Technique: 3D Reflow

This special technology reduces rejection rate as well as saves cost by completing three-dimensional reflow soldering at one time on low heat-resistant parts which are difficult to work with.

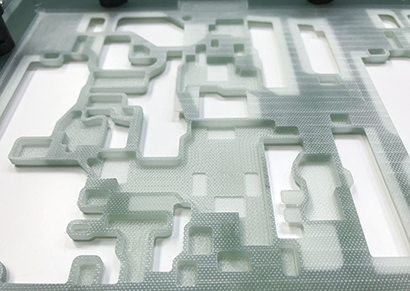

Dip Pallet

Certified as Kyoto Oscar for its unique Dip Pallet Design Optimization Business.

*Kyoto Oscar Certification

A system to certify companies engaged in excellent businesses as defined by the Kyoto Institute of Advanced Technology.

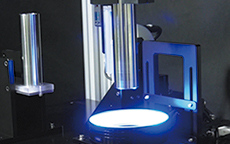

Image Inspection Equipment

We offer image inspection devices crafted to suit customers’ requests through our collaboration with device manufacturers. Where required we can also incorporate AI software.