Delivering One-of-a-kind

Technology and Quality

With over 35 years of overseas manufacturing experience, Kyoseki Sangyo's strength comes from the craftsmanship of our local staff who are dedicated to our philosophy of “sincerity and integrity” and committed to “observing the basics,” as well as from our unrivaled facilities and responsiveness in each region we operate.

-

Ladkrabang, Bangkok, THAILAND

KYOSEKI AUTOMOTIVE PIPING CO., LTD.

First Factory

Second Factory

Our Thailand facility is the group's largest plant, handling the entirety of the manufacturing process from design through production. It principally produces and exports automotive air-conditioner piping to Southeast Asia, Japan and North America. As of 2022 the plant has become a Tier 1 supplier (supplying directly to automobile manufacturers) and continues to grow more reliable by consistently outputting high quality products.

Certified

ISO 9001

IATF 16949

ISO 14001

TLS 8001

-

Port Klang, Kuala Lumpur, MALAYSIA

KYOSEKI SANGYO (MALAYSIA) SDN., BHD.

Our Malaysia factory conducts slitting and punching for industrial films used in such products as semiconductors and liquid crystals. Equipped with one of the few clean-room environments in the region, it is valued highly in a broad area which includes Indonesia, Thailand, Sri Lanka, and Singapore as neighbors.

Equipped with a

Class 10000

clean room

Certified

ISO 9001

ISO 14001

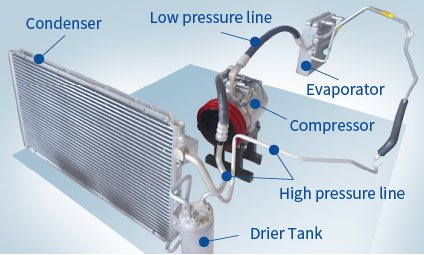

Aluminium piping and hoses for car air conditioning system

Our Thai operation designs and produces genuine parts for Japanese auto makers and exports them to Southeast Asia, Japan, and North America. In 2017, Kyoseki Automotive Piping achieved Tier One supplier status (supplying direct to auto makers), and continues to earn customer trust with its superior technology and craftsmanship. The company has set itself the ambitious target of capturing 10 percent of global market share.

Car Air Conditioning System

Manufacturing Process

-

1.Bending

-

2.Chamfering

-

3.Terminal processing

-

4.Brazing

-

5.Crimping